Feb 15, 2023 12:55:55 PM

.jpg?width=596&name=Pressure%20Recovery%202%20(1).jpg)

Pressure Recovery Across Expanders

It is a common notion that fluid will flow for a system where static pressure from the origin is higher than the static pressure at the destination. However, some components can demonstrate the opposite, flow occurs from low to higher static pressure without any addition of work or energy from an outside source. This is best observed across a pipe expander. A piping component that connects two (2) pipes of dissimilar sizes with the upstream side having a smaller size than the pipe connected downstream.

Image 1: Sample Expander Installation

The phenomena experienced by expanders as described above is called “Pressure recovery”. As the fluid flows from a small pipe at a relatively higher velocity to a larger pipe at a relatively lower velocity, the reduction in velocity translates to a mechanical energy balance where static pressure downstream of the expander increases.

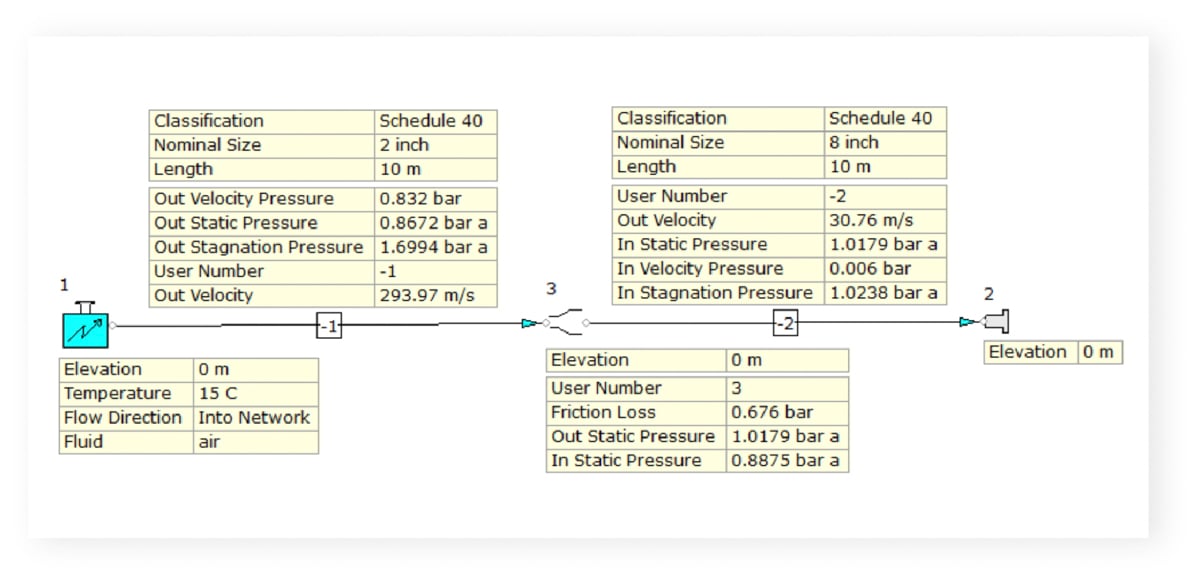

A FluidFlow user queried if the software takes pressure recovery across an expander into account. To demonstrate how FluidFlow handles this, we utilized a system example as presented in Image 2.

The system takes air as the fluid supplied at 1000 l/s with a temperature of 15°C on a Known or Assigned Flow node. This is discharged to the atmosphere using two (2) carbon steel pipes sized 10 m x 2 inch Sch 40 and a 10 m x 8 inch Sch 40 connected using an expander.

Image 2: Sample System Hydraulic Model

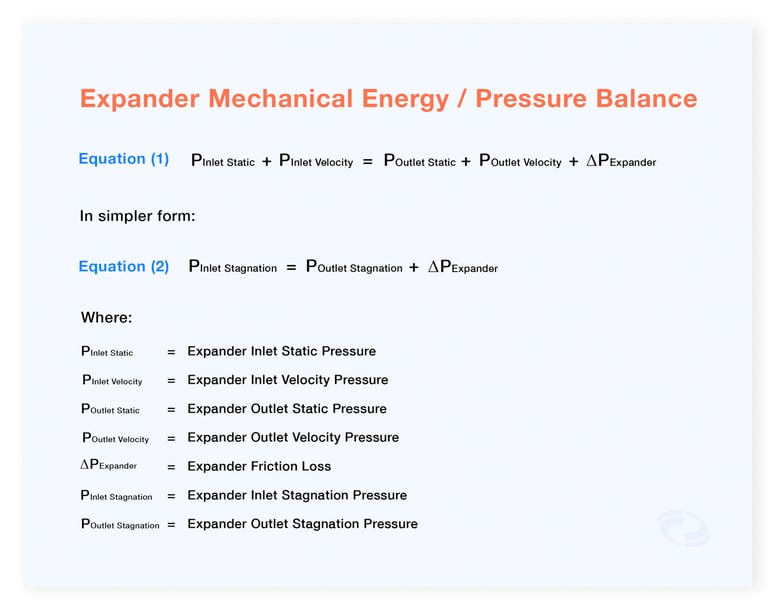

When we try to develop a mechanical energy balance across the expander, we can represent it as:

Image 3: Mechanical Energy / Pressure Balance across pipe expander

Image 3: Mechanical Energy / Pressure Balance across pipe expander

The pressure recovery for the expander can be characterized from the "Expander Outlet Static Pressure". We say that it is recoverable since a portion of the fluid's kinetic energy is converted back as static pressure while the remaining balance accounts for friction loss. This occurs as it passes from a high to low velocity across the expander.

To further illustrate how this gets captured in the software, let’s see FluidFlow calculation results for the sample system:

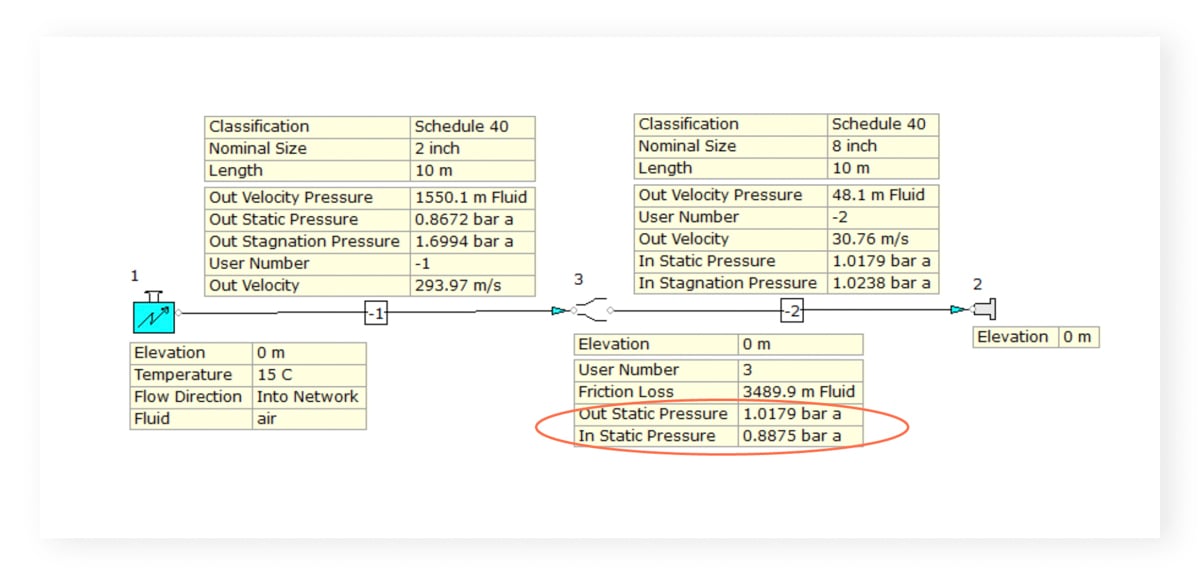

Image 4: Calculated Sample System Hydraulic Model

It can be observed that the Expander outlet static pressure is higher than the Expander Inlet Static Pressure indicating pressure recovery across. However, this pressure recovery is significantly lower than the expander friction loss. As such, it can go unnoticed unless more deeper analysis is made on the system especially on small volumetric rates or pipe size changes.

In summary, connecting two pipes of dissimilar sizes through a pipe expander enables the conversion of a portion of the fluid's kinetic energy into static pressure, resulting in an increase in the downstream static pressure. Although unusual, pressure recovery similar to that occurring across an expander, is an important consideration when analyzing the behavior of fluid systems.

This concept can be modeled and analyzed using FluidFlow. Understanding how this phenomena occurs provides insights on how it can be managed to optimize design across pipe connections.

Do you have any questions on the article or anything fluid flow related? Send us an email at success@fluidflowinfo.com.