Check Valves

The main function of a check valve is to protect mechanical equipment in a piping system by preventing the reversal of flow by the fluid. Check Valves (also called Non-Return Valves) are unidirectional. Flow is only allowed to pass in one direction, and this property has many uses in flow systems. An example would be to place a non-return valve on the discharge side of a pump/compressor, where backflow could damage the internals of the equipment and cause an unnecessary shutdown of the system.

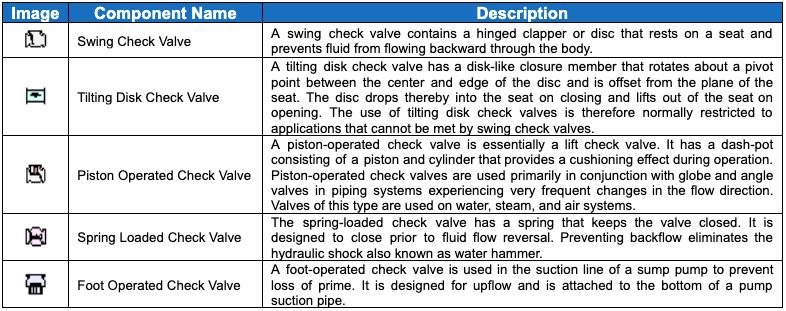

The table below shows the application of different check valve components available in the FluidFlow database:

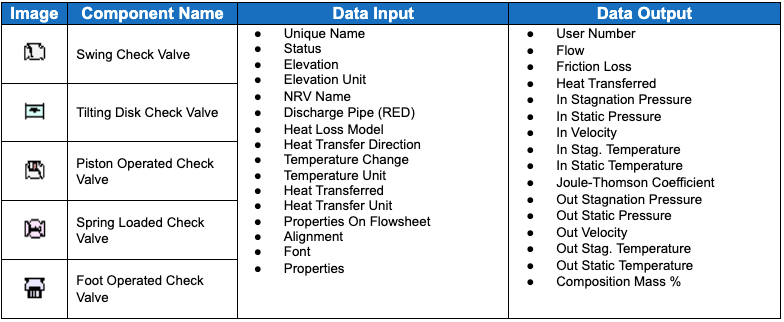

The table below shows the required data input and the output for the check valve components. Note that the results table varies depending upon the fluid phase state and the visible properties selected by the user.