Boundaries

Hydraulic models operate with single or multiple origins and destination points. These "points" are called boundaries within the concept of FluidFlow. Boundaries are therefore the points where the model starts and terminates.

Correct selection of model start and end boundaries is a simple skill you should know in order to build your model.

FluidFlow has many types of boundaries available. Generally, at a network boundary, you will either know (or have as a design goal) the pressure or the flow rate. In FluidFlow, when we define the pressure at a boundary node, the software calculates the resultant flow rate and vice versa.

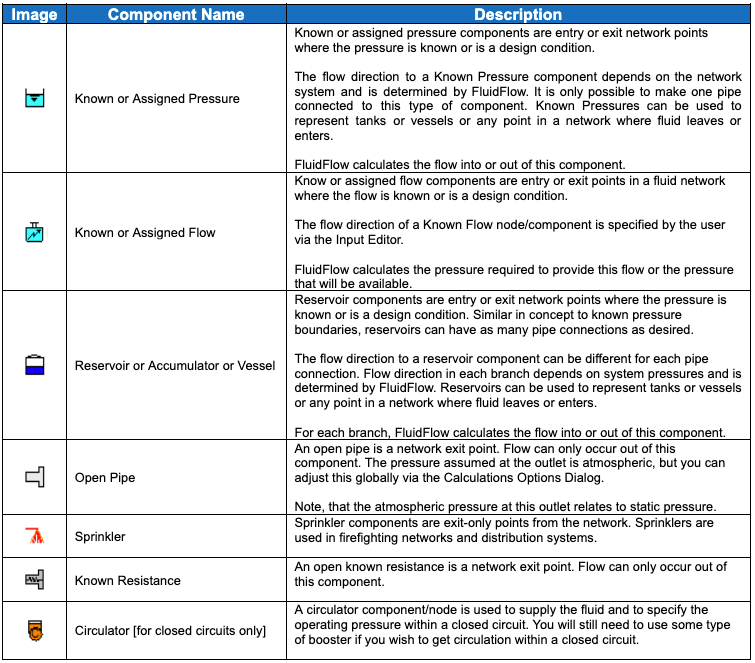

The table below shows the application of different boundary components available in the FluidFlow database:

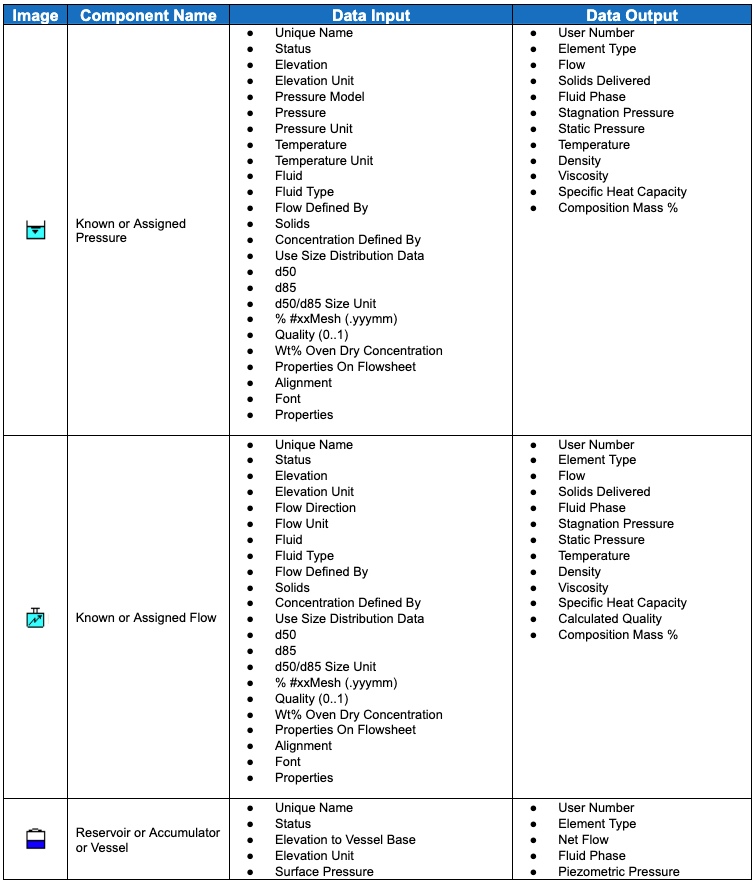

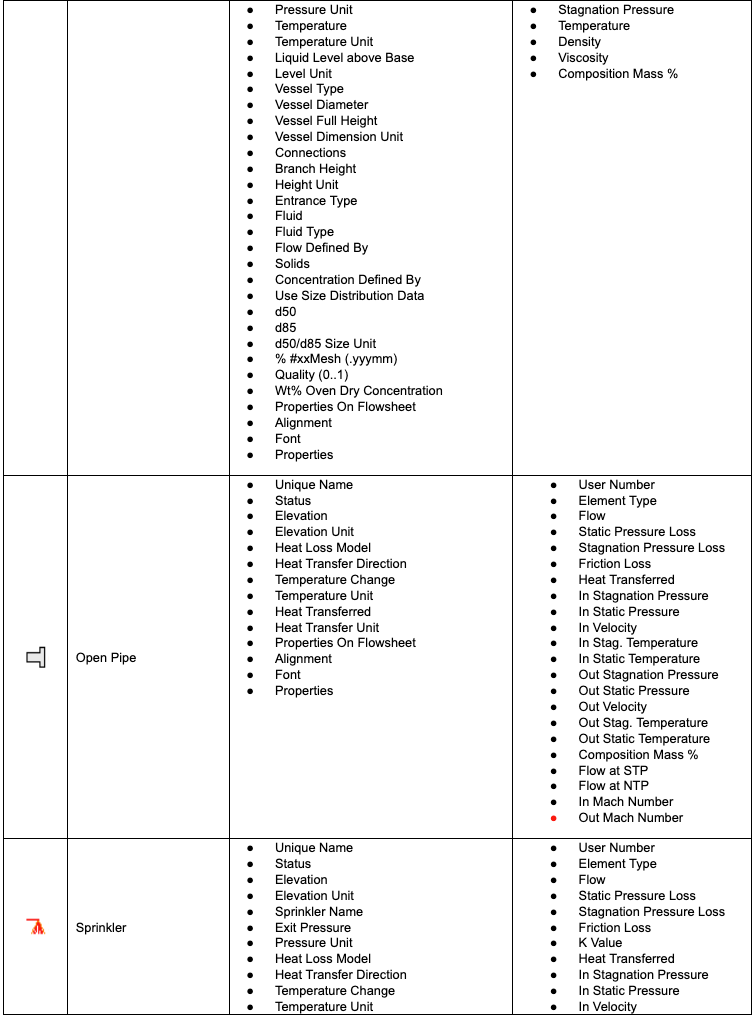

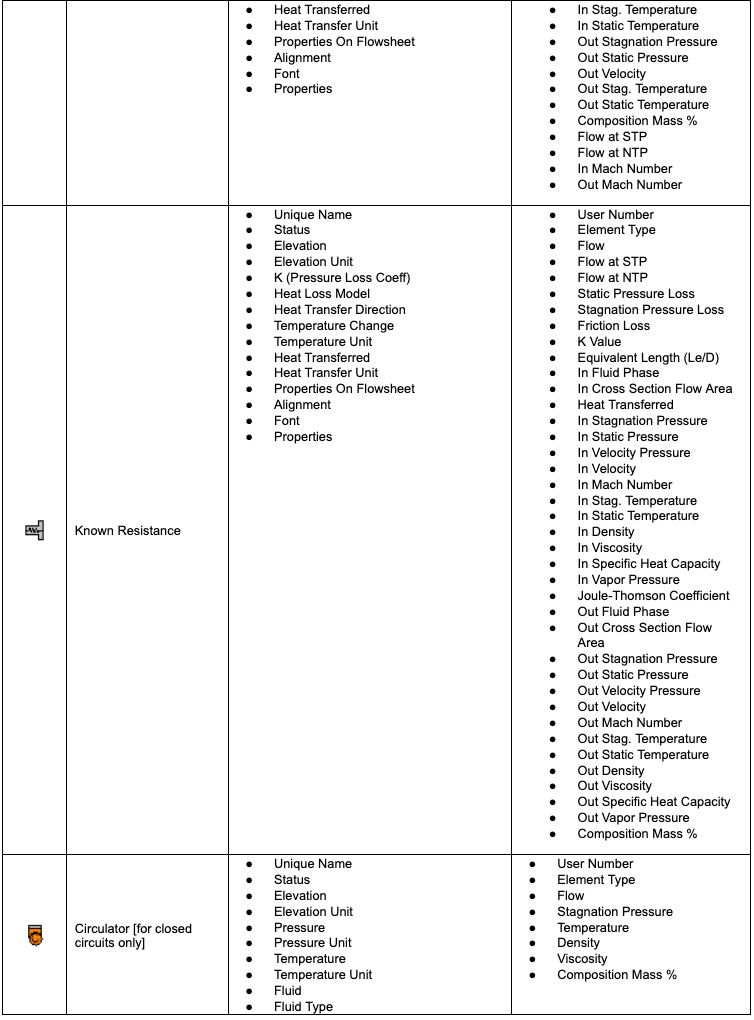

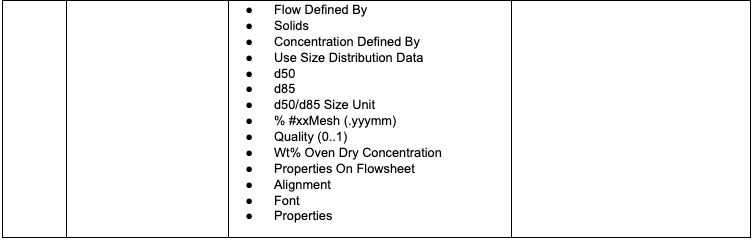

The table below shows the required data input and the output for the boundary components. Note that the results table varies depending upon the fluid phase state and the visible properties selected by the user.