Learn how to accurately model vacuum pumps in FluidFlow with this comprehensive guide covering vendor data interpretation, step-by-step implementation, best practices, and solutions to common challenges.

Introduction

Vacuum pumps are essential components in many fluid systems requiring sub-atmospheric pressure conditions. This guide outlines the process for implementing these critical elements in your FluidFlow models, enabling engineers to predict system performance, optimize designs, and troubleshoot existing installations with confidence.

FluidFlow provides robust capabilities for modeling vacuum systems alongside other fluid flow networks. Accurate vacuum pump modeling ensures reliable simulation results, particularly in processes requiring precise pressure control such as distillation, filtration, degassing, and vacuum drying operations.

Understanding Vendor Performance Data

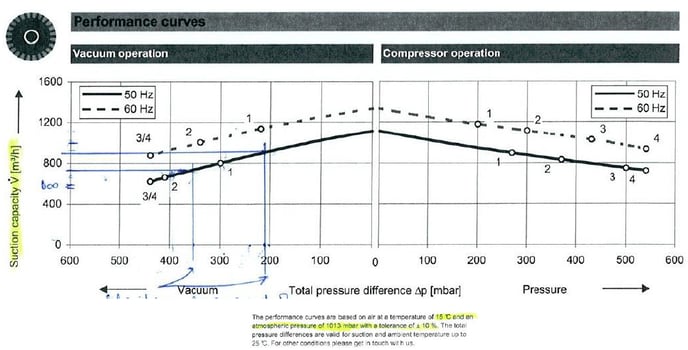

Figure 1: Vendor Vacuum Pump Performance Data.

Figure 1 shows a typical example of performance data for a vacuum pump as supplied by a vendor. This data typically includes:

- Volumetric flow rates at different suction pressures

- Reference conditions (temperature and pressure) for the flow rates

- Performance curves for different operating frequencies (typically 50 Hz and 60 Hz)

- Power consumption data

Note: The actual appearance of Figure 1 would show vendor performance curves. In your implementation, you should refer to your specific vendor documentation.

Step-by-Step Implementation in FluidFlow

Step 1: Add New Vacuum Pump

- Open your FluidFlow project

- Navigate to Database → Boosters → Fan or Compressor

- Click Add

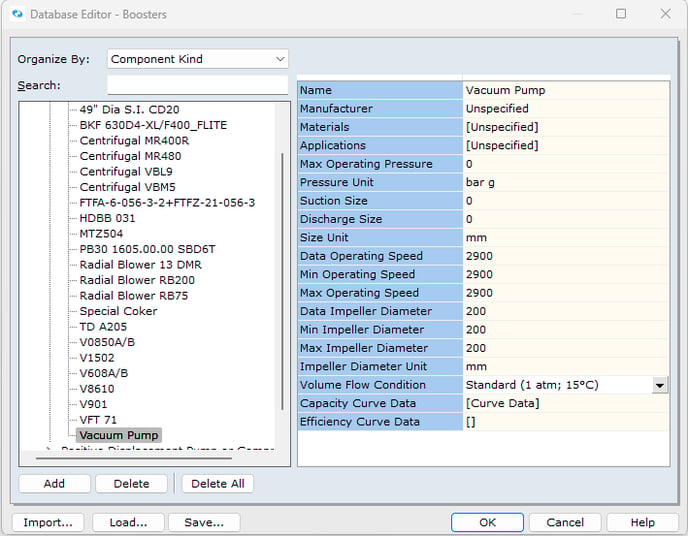

Step 2: Configure Volume Flow Conditions

Ensure the volume flow conditions in FluidFlow match those specified in the vendor data:

- Set Volume Flow Condition as specified in vendor data

- Verify that the temperature and pressure values match those in your vendor documentation (Figure 2 shows Volume Flow Conditions set to STP based on the highlighted data at the bottom of Figure 1)

Figure 2. Specify Volume Flow Condition.

Important: Mismatched reference conditions will lead to inaccurate simulation results. Always check the fine print on vendor data sheets.

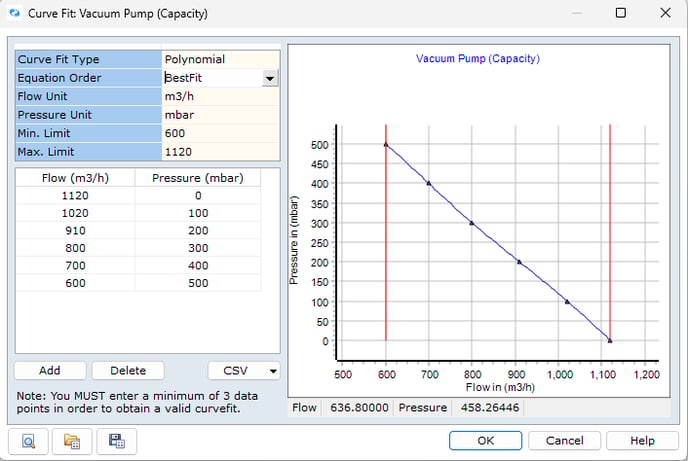

Step 3: Enter Performance Curve Data

-

Select the appropriate frequency curve (e.g., 50 Hz) from the vendor data

-

Enter the suction pressure values and corresponding flow rates as coordinate pairs

-

Include sufficient points to accurately represent the entire curve

-

Select the equation order (or choose BestFit to let the solver automatically determine the optimal equation)

Figure 3. Input Vacuum Pump Performance Curve Data.

Best Practices for Vacuum Pump Modeling

- Verify Units – Ensure all units (pressure, flow rate, temperature) are consistent between the vendor data and FluidFlow settings

- Complete Data Range – Enter the full range of the performance curve, from maximum vacuum to minimum vacuum, for accurate interpolation

- Consider Operating Frequency – Use the performance curve that matches your system's electrical supply frequency

- Multiple Operating Points – Include at least 5-7 data points to ensure smooth curve interpolation

- Check Data Consistency – Verify that entered data creates a monotonic curve without anomalies

- Validate Model – Run a simple test simulation to verify the pump behaves as expected before incorporating it into complex systems

Common Pitfalls to Avoid

- Using incorrect reference conditions for volumetric flow rates

- Misinterpreting vendor data units (e.g., confusing absolute and gauge pressures)

- Entering insufficient data points, leading to inaccurate curve interpolation

- Overlooking temperature effects on vacuum pump performance

FAQs

Q: Can FluidFlow model different types of vacuum pumps?

A: Yes, FluidFlow can model various vacuum pump technologies. The key requirement is having the appropriate performance curve data.

Q: How do I handle vacuum pumps with multiple stages?

A: Multi-stage vacuum pumps can be modeled either as a single component using the combined performance curve, or as individual pumps connected in series if you have stage-specific data.

Q: What if my vendor data uses different reference conditions than standard STP?

A: You can convert all performance data to consistent reference conditions before entering into FluidFlow. Use gas laws to adjust volume flow rates for different temperature and pressure references.

Q: How do I model variable speed vacuum pumps?

A: For variable speed pumps, you can either enter multiple performance curves at different speeds or use FluidFlow's built-in affinity laws to scale from a base curve.

Q: Can I model vacuum pump performance degradation over time?

A: Yes, you can create multiple scenarios with adjusted performance curves to simulate the effects of wear, fouling, or other forms of degradation to reflect actual operating conditions.

Conclusion

Accurate modeling of vacuum pumps in FluidFlow requires careful attention to vendor data, proper reference conditions, and complete performance curves. Following the steps and best practices outlined in this guide will help ensure your vacuum system simulations provide reliable results for design and operational decisions.