Learn how to create and interpret composite pump curves in FluidFlow to optimize pump system design, predict performance, and improve operational efficiency.

Introduction

Composite pump curves in FluidFlow provide powerful visualization tools for understanding how multiple pumps perform together in series or parallel configurations. These curves transform complex performance data into intuitive visual representations, helping engineers predict system behavior, optimize pump combinations, and ensure systems remain efficient across varying flow demands.

Composite pump curves allow you to visualize combined pump performance, predict operation under various scenarios, and select the optimal pump arrangement for your specific application—preventing oversizing and operational inefficiencies before they occur.

Key Benefits

- Visualize the combined performance of multiple pumps in one clear chart

- Predict system operation under varying process demands

- Select the optimal pump arrangement for specific applications

- Communicate system capabilities clearly to stakeholders

- Troubleshoot performance issues in existing multi-pump systems

Understanding Pump Configurations

Pumps in Parallel

Parallel pump arrangements combine multiple pumps to increase flow capacity while maintaining the same head capability:

- Primary benefit: Increased flow capacity at a given head

- Ideal applications: Variable flow systems, water distribution networks

- Configuration notes: Typically similar pumps, though dissimilar models can be used

- Required components: Non-return valves to prevent unwanted circulation

- Common examples: Water distribution systems, large building services

Pumps in Series

Series pump arrangements stack multiple pumps to increase head while maintaining the same flow capacity:

- Primary benefit: Increased head capability at a given flow

- Ideal applications: High-head systems, long-distance transport

- Configuration notes: Used when a single pump cannot achieve the required head

- Required components: May need bypass lines and non-return valves

- Common examples: Long-distance transport of tailings, ash, or concentrates

Creating Composite Pump Curves in FluidFlow

- Build your desired pump configuration in your model

- Add pumps, piping, and necessary components

- Ensure all pumps have appropriate performance data

- Access the composite chart tool

- Go to Tools → Composite Chart

- Configure the composite chart

- Open the Parallel and Series Pumping tab

- Select operational pumps for inclusion in the analysis

- Choose either parallel or series configuration

- Generate the composite chart

- Click PLOT to create the visualization

- Review the resulting chart showing individual and combined performance

- Configure the chart to display essential information (composite and individual curves, system curve, duty point) or adjust measurement units

- Analyze results

- Identify the system operating point (intersection with system curve)

- Compare different configurations if needed

Interpreting Composite Pump Charts

A typical FluidFlow composite pump chart displays these key elements:

- Individual pump curves – Lighter dashed lines that show each pump's performance capacity

- Composite curve – A solid blue line representing the combined pump performance

- System curve – A thin black line that represents the overall system resistance

- Duty Point – A small triangle indicating the actual operating point where the system and composite pump curves intersect

Parallel Pump Interpretation

For pumps in parallel, the composite curve demonstrates:

- Increased flow capacity for a given head value

- Flow values add horizontally at any given head point

Series Pump Interpretation

For pumps in series, the composite curve shows:

- Increased head capability for a given flow rate

- Head values add vertically at any given flow point

Illustrative Example

Parallel Pump Configuration Example

Pumps installed in parallel are typically identical pumps, but there may be applications where dissimilar pumps are used. Consider a system with four pumps in parallel, with three currently operational:

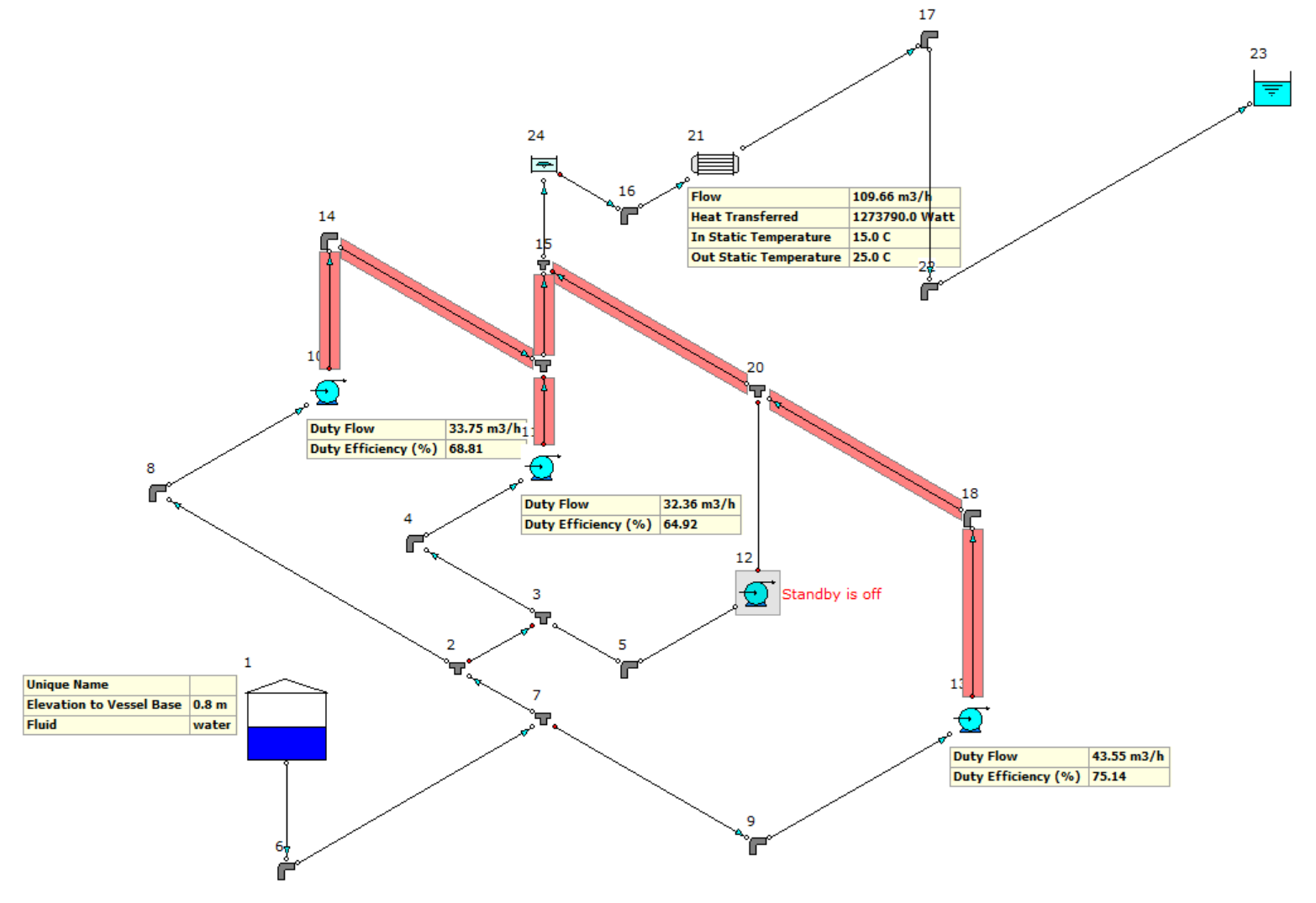

Figure 1. Dissimilar Pumps in Parallel.

-

Each individual pump contributes to the total flow capacity at a given head

-

When using dissimilar pumps (different sizes), FluidFlow can generate accurate composite curves for any combination

-

Figure 2 shows an example with dissimilar pumps (Pump 10 and 11) operating in parallel

Figure 2. Composite Pump Chart – Dissimilar Pumps in Parallel.

-

The composite curve clearly illustrates how these different-sized pumps perform together in the system

Series Pump Configuration Example

Many pumping applications require fluids to be transported over long distances and against high heads that exceed what a single pump can develop. Examples include pumping tailings, power station ash, underground fill, and concentrates.

-

When pumps are installed in series, the head values add vertically at any given flow rate

-

The composite pump chart for pumps installed in series can be plotted in FluidFlow:

Figure 3. Composite Pump Chart – Similar Pumps in Series.

Integrating Composite Charts into Your Workflow

FluidFlow allows you to make the most of composite pump charts:

- In newer versions, composite charts automatically update when you recalculate the model

- You can insert the chart directly into your flowsheet using the "Insert in Flowsheet" menu item (in FluidFlow 3.54+)

- Charts can be exported for inclusion in reports and presentations

FAQs

Q: Can I mix different pump sizes or types in a composite curve analysis?

A: Yes, FluidFlow supports composite curves for dissimilar pumps in both parallel and series configurations, allowing you to model mixed pump installations accurately.

Q: How do I exclude non-operational pumps from my analysis?

A: Set non-operational pumps to Off or Closed in the Input Editor before generating the composite curve. Only pumps set to "On" and selected from the Composite Chart Setup dialog will be included in the analysis.

Q: Can I analyze variable speed effects on composite pump curves?

A: Yes, adjust pump speed settings in the pump data to see how speed changes affect the composite curve. This is valuable for VFD applications.

Q: How accurate are the curves for dissimilar pumps in parallel?

A: FluidFlow calculates these accurately using hydraulic principles, eliminating the complex manual calculations that would otherwise be required.

Q: Can I create composite curves for pumps with different fluids?

A: Pumps must be handling the same fluid for accurate composite curve generation. Different fluid properties would affect pump performance differently.

Conclusion

FluidFlow's composite pump curves offer powerful visualization tools for understanding how multiple pumps work together in your system. With this feature, engineers can select ideal pump combinations, predict system performance across varying conditions, and communicate design decisions effectively.

Mastering composite pump curves empowers engineers to design more flexible, energy-efficient pumping systems that adapt to changing flow requirements while avoiding costly oversizing or operational problems that often result from inadequate visualization of multiple pump interactions.