Discover how to effectively model positive displacement pumps in FluidFlow, including performance correction, slip data implementation, and best practices for predicting real-world performance.

Introduction

Positive Displacement (PD) pumps operate by trapping a fixed amount of fluid and forcing it from the inlet to the outlet. Unlike centrifugal pumps that generate flow by increasing the fluid's kinetic energy through impeller rotation, PD pumps create flow by physically displacing the fluid. This fundamental difference means PD pumps:

- Deliver nearly constant flow regardless of discharge pressure

- Provide more precise flow control for applications requiring accuracy

- Are self-priming and can handle higher viscosity fluids

- Generate higher pressures at lower flow rates compared to centrifugal pumps

FluidFlow software enables engineers to model PD pumps with high accuracy, accounting for critical factors like slip, efficiency corrections, and performance degradation that are essential for realistic system modeling and performance prediction.

PD Pump Options in FluidFlow

FluidFlow offers two primary options for modeling positive displacement pumps, depending on the information available:

1. Positive Displacement Pump or Compressor

This option requires input for performance correction or volumetric efficiency factor.

- By default, volumetric efficiency factor is set to 1 unless specified otherwise in the pump database

- Duty flow calculation: Operating Speed × Displaced Volume per Revolution × Performance Factor

- The performance factor accounts for pump slippage or performance degradation as a function of pump speed

Required vendor information for database entry:

- Max Operating Pressure

- Max Operating Speed

- Pump Suction and Discharge pipe size

- Pump Efficiency

- Displaced Volume per Revolution

- Performance Factor

2. Rotating Positive Displacement Pump

This option requires slip capacity data, which is dependent on fluid viscosity.

- Slip refers to the amount of fluid that remains in the pump cavity, reducing the actual fluid delivered

- Screw pumps are a typical example of rotating PD pumps

- Flow remains nearly constant regardless of pressure, but is sensitive to viscosity effects

Required vendor information for database entry:

- Max Operating Pressure

- Max Operating Speed

- Pump Suction and Discharge pipe size

- Pump Efficiency

- Displaced Volume per Revolution

- Max Viscosity Limit

- Slip Data

Accessing the PD Pump Library in FluidFlow

FluidFlow includes a comprehensive library of PD Pumps and Rotating PD Pumps that users can:

- Select from existing models in the library for immediate use

- Add new pump models as needed — once added, they are stored in the database and available for all future projects

Defining a PD Pump in the Database

When adding a Positive Displacement Pump to the database, the key setting to define is "Use Performance Correction", which can be set to Yes or No:

- Choosing "No" → FluidFlow automatically applies a correction factor of 1

- Choosing "Yes" → You must define the curve relationship for Performance Factor (a measure of performance degradation as a function of pump operating speed)

Understanding the Performance Correction Factor

The Performance Factor:

- Represents performance degradation due to operational conditions

- Typically ranges between 0 and 1

- Accounts for pump slippage and performance decline at different pump speeds

Defining a Rotating PD Pump in the Database

When adding a Rotating Positive Displacement Pump to the database, slip data or information on slip capacity vs. viscosity is required.

Slip and Its Impact on PD Pump Performance

Slip is a major factor affecting PD pump performance:

- In ideal conditions, the expanding inlet cavity is filled with fluid from the inlet pipeline

- When slip occurs, some fluid from the discharge side flows back to the inlet side through pump clearances

- Slip reduces effective flow and overall pump performance

Key Insight: The degree of slip directly influences PD pump performance and is affected by:

- Fluid viscosity

- Internal clearances

- Pump geometry

- Differential pressure

Calculating Pump Slip When Data is Unavailable

If slip data is not available, you can still use the rotating positive displacement pump by calculating slip using flow rate vs. head data for specific viscosities:

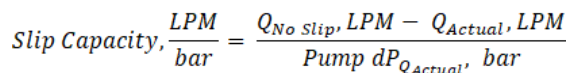

-

Get the pump output at no slip condition (QNo Slip). This is the pump flow at zero differential head and is not affected by changes in viscosity

-

Subtract from QTheoretical the pump output (QActual) at varying differential head and viscosity to determine how much flow rate is lost via slip

-

Calculate Slip Capacity

Note: The value of slip capacity is constant for a given liquid viscosity.

Using the Auto-size Feature

Alternatively, you can use the Auto-size feature of FluidFlow and specify the design flow requirement for your pump:

- This is commonly used during the initial design stage when limited information is available

- Helps determine the required booster differential pressure to meet the system design flow

Best Practices

- Always verify the Performance Factor curve when "Use Performance Correction" is set to Yes

- Use manufacturer data when available to define slip-related performance loss

- Avoid assuming zero slip — this can lead to overly optimistic performance predictions

- Consider viscosity effects on slip, especially for rotating PD pumps like screw pumps

- For high-viscosity applications, pay special attention to slip data accuracy

- Remember that PD pump flow is less affected by pressure changes but more by viscosity compared to centrifugal pumps

FAQs

Q: Do I need to re-add the same PD Pump for each project?

A: No, once added to the database, the pump is available for all future projects.

Q: What is the typical range for Performance Factor?

A: Between 0 and 1, depending on speed, slip, and other operational factors.

Q: How do I choose between a standard PD pump and a Rotating PD pump node in FluidFlow?

A: Choose based on available data: use the standard PD pump when you have performance factor data, and the Rotating PD pump when you have slip capacity data related to viscosity.

Q: Can I model a screw pump in FluidFlow?

A: Yes, screw pumps are typically modeled using the Rotating PD Pump option as they are particularly sensitive to slip caused by viscosity, internal clearances, and pump geometry.

Q: What should I do if I don't have manufacturer slip data?

A: You can calculate slip using flow rate vs. head data at different viscosities, or use the Auto-size feature during preliminary design stages.

Conclusion

Modeling PD Pumps in FluidFlow is straightforward when efficiency corrections and performance factors are defined correctly. Understanding slip behavior ensures accurate flow predictions and reliable system design. The software offers flexible options based on available data, whether using the standard PD Pump model, the Rotating PD Pump model, or the Auto-size feature for preliminary design.

By correctly modeling PD Pumps in FluidFlow, engineers can accurately predict system performance, account for slip losses, and ensure optimal equipment selection, ultimately leading to more efficient designs and reduced operational issues in real-world applications.