Feb 18, 2022 1:20:58 PM

Applying the Pump Affinity Laws in FluidFlow to Predict Pump Performance.

A previous blog post titled “The Application of Pump Affinity Laws to Predict Pump Performance” https://blog.fluidflowinfo.com/the-application-of-pump-affinity-laws-to-predict-pump-performance discussed the general principles of the pump affinity laws and how the Affinity Laws can be used to predict the changes in pump performance with a variation in pump speed or impeller diameter.

In this previous blog, it was demonstrated how changing either of these two parameters has a knock-on effect of changing the pump flow, head, NPSH, and power curves as well as offering potentially significant energy savings if the pump speed can be reduced. Since significant energy savings can be achieved by reducing pump speed, the Affinity Laws, therefore, become a particularly useful tool in determining the effect of reducing the pump operating speed on system performance.

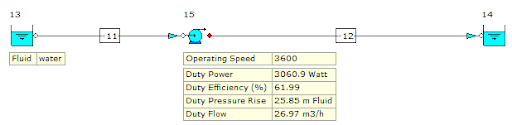

This blog simply demonstrates how the affinity laws are applied within FluidFlow. Figure 1 shows an example water pipeline featuring a pump operating at a speed of 3600 RPM. The duty of the pump has been calculated as 26.97 m3/h at 25.85 m fluid with a power requirement of 3060.9 watts and an efficiency of 61.99 %.

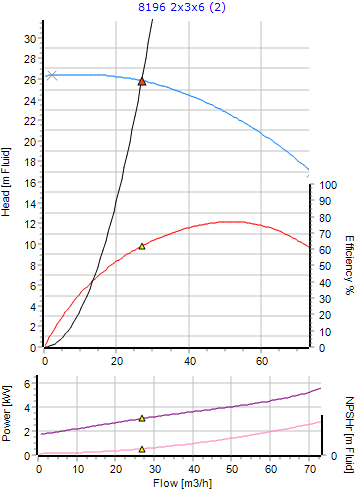

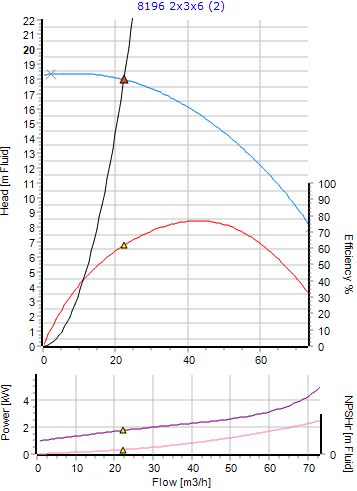

Figure 2: Pump Curves at 3600 RPM.

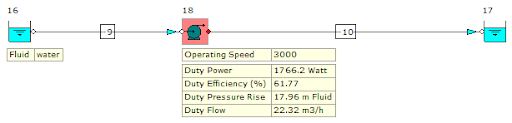

If the pump speed was then adjusted to 3000 RPM, we would expect the flow rate to reduce. Using the affinity laws, the software predicts the new flow rate as shown in Figure 3.

Figure 3: Pump Performance at 3000 RPM.

The new duty of the pump has been calculated as 22.32 m3/h at 17.96 m fluid with a power requirement of 1766.2 watts and an efficiency of 61.77 %. As the power required is directly proportional to the cube of the speed, we can see the dramatic reduction in pump power required.

We can see the pump node is highlighted in red indicating that there is a warning message associated with the pump. The pump has a warning message which notes that the affinity laws have been applied as a result of the speed change from 3600 to 3000 RPM. This allows the user to see instantly that the pump operating speed in the system has been changed.

Figure 4 provides an overview of the duty-point on the pump curves at this new speed of 3000 RPM.

Figure 4: Pump Curves at 3000 RPM.

Since significant energy savings can be achieved by reducing pump speed, the Affinity Laws become a particularly useful tool in determining the effect of reducing the pump operating speed on system performance.

Although the Affinity Laws can be used to predict the performance of changing pump speed or impeller diameter and indeed, the performance of geometrically similar pumps, it has generally been accepted that the application of the Affinity Laws should be limited to around 10 to 20% owing to the likelihood impellers not being geometrically identical.